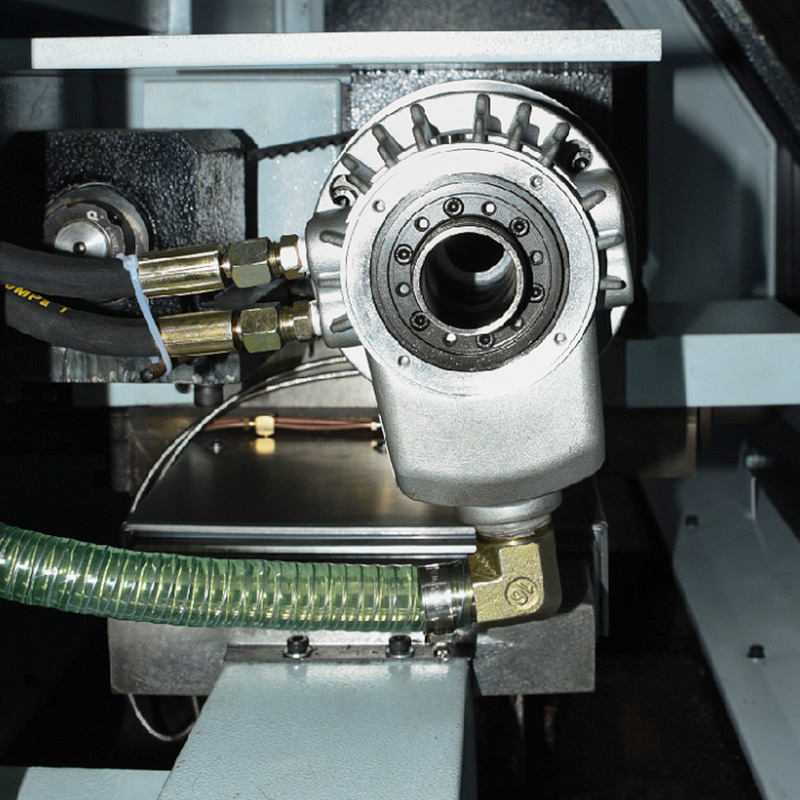

CF32 Hydraulic Clamping CNC Polygon Turning Machine

Cat:Small Polygon Lathe

CF32 hydraulic clamping CNC polygon lathe is designed for milling small and medium-sized high-precision parts, which can mill square, octagonal, hexag...

See DetailsThe metal lathe machine factory, a foundational tool in machining and manufacturing, operates on the principle of rotating a workpiece against a stationary cutting tool to remove material. Its evolution has led to the development of various types, each designed to address specific production requirements, workpiece dimensions, and levels of operational control. These machines can be systematically classified based on their size and configuration, their level of automation, and their specialized function.

1. Classification by Size and Configuration

The physical size and structural layout of a lathe directly influence the size of the workpiece it can accommodate and the nature of the operations it can perform.

Bench Lathe: This is a small lathe mounted on a workbench, designed for precision work on small parts. Clockmakers, model engineers, and jewelers often use bench lathes for intricate tasks where high accuracy is required on components with minimal mass. Their compact size makes them suitable for workshops with limited floor space, but their light construction limits their ability to handle large workpieces or make heavy cuts.

Engine Lathe / Center Lathe: This is the common and versatile type of lathe, forming the standard image of the machine for many. It is characterized by a horizontal bed, a headstock containing the spindle and gear train, a tailstock for supporting the end of long workpieces, and a carriage that holds and moves the cutting tool. Its name originates from the original line-shaft-driven "engine" lathes of the industrial revolution. Engine lathes are general-purpose machines capable of turning, facing, drilling, boring, and threading. A common example of their use is in a maintenance workshop for machining a new shaft for a pump or repairing a worn thread on a piece of equipment.

Gap Bed Lathe: This is a variant of the engine lathe designed with a removable section in the bed, located just behind the headstock. This "gap" allows the lathe to swing workpieces of a larger diameter than the bed would normally permit. For instance, machining a large flywheel or a pulley would require a gap bed lathe. The gap piece can be reinstalled for regular work, making it a flexible solution for shops that occasionally need to handle oversized components.

2. Classification by Level of Automation

The degree to which the machining process is controlled by human intervention versus a programmed system defines a major division in lathe types, impacting production speed and consistency.

Manual Lathe: On a manual lathe, every action—from engaging the spindle to moving the cutting tool—is directly controlled by a human operator using handwheels and levers. The skill of the machinist determines the accuracy and finish of the final part. While this offers high flexibility for one-off jobs or repairs, it is dependent on operator skill and is generally slower for repetitive tasks. Training a skilled manual machinist requires a significant investment of time.

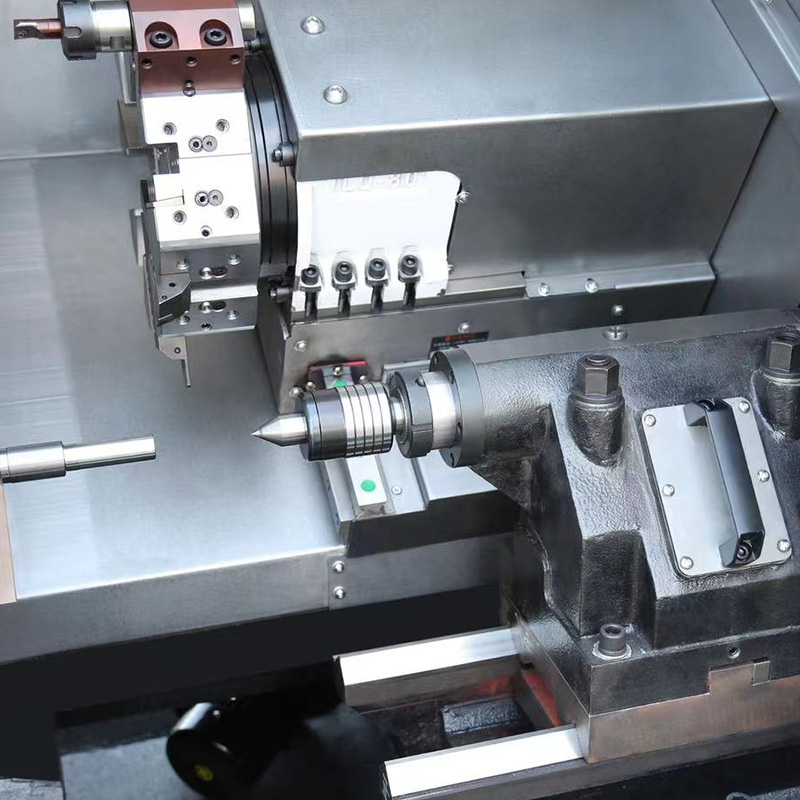

CNC Lathe (Computer Numerical Control): In a CNC lathe, a computer program dictates all movements of the tool and workpiece. The operator's role shifts from direct control to programming, setup, and supervision. This automation allows for the highly repeatable production of complex geometries with minimal variation between parts. In an automotive factory, CNC lathes are used to produce thousands of identical engine pistons or transmission shafts with a high degree of consistency. They can also perform complex operations like contouring that would be challenging to execute manually.

Swiss-Type Lathe (Sliding Headstock Lathe): This is a specialized form of CNC lathe designed for high-volume production of very small, slender parts. In a Swiss-type lathe, the headstock and workpiece slide axially through a guide bushing, which provides support very close to the cutting tool. This configuration minimizes deflection, allowing for precise machining of long, thin components like watch screws, medical pins, and connector pins. Their design is optimized for efficiency in mass production, often incorporating multiple tools that operate simultaneously.

3. Classification by Specialized Function

Beyond general-purpose machines, some lathes are engineered for specific, repetitive tasks or for handling workpieces of a particular nature.

Turret Lathe: This lathe, which can be manual or CNC, features a hexagonal turret that holds multiple cutting tools. Instead of changing tools manually, the operator or program can index the turret to bring different tools into position rapidly. This design is efficient for producing duplicate parts in a batch production environment, as it reduces setup time between operations. Capstan lathes are a smaller, lighter version of the turret lathe, often used for smaller workpieces.

Vertical Turret Lathe (VTL): A VTL reorients the lathe's axis to a vertical position. The workpiece is mounted on a horizontal rotating table, and the cutting tools are suspended from a cross-rail. This configuration is advantageous for handling very heavy, short, and large-diameter workpieces that would be difficult to mount on a horizontal lathe. Examples include machining large gears, turbine rotors, and heavy flanges, where gravity works to secure the part firmly to the table.