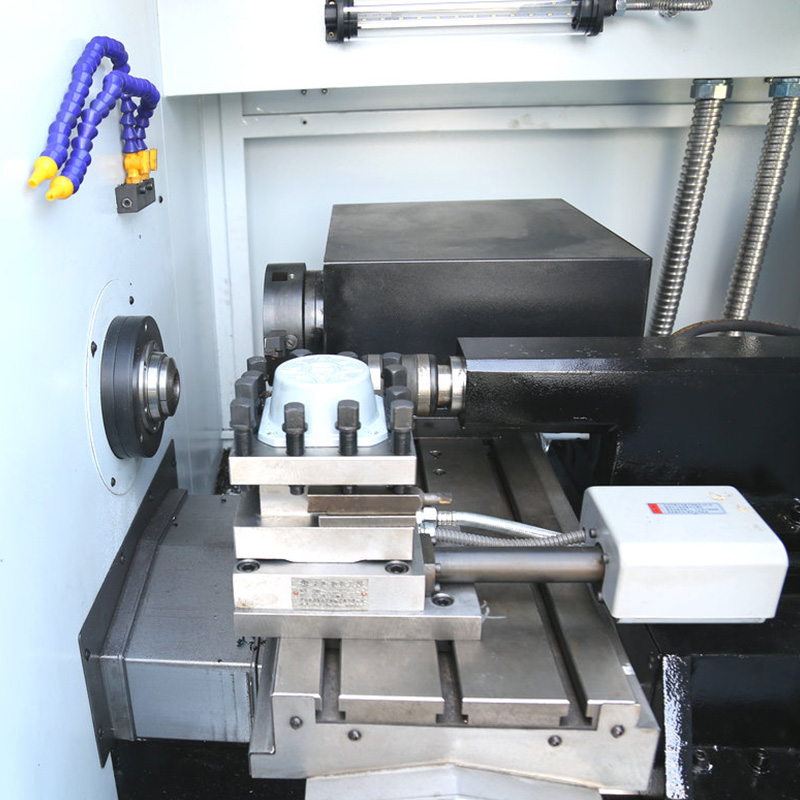

CF60 CNC Polygon Lathe

Cat:High Rigidity Polygon Lathe

The CF60 CNC Polygon Lathe is a highly efficient and versatile machine tool designed for small to medium-sized precision parts milling. It is capable ...

See Details1. Enhancing Precision and Consistency in Manufacturing

One of the primary problems addressed by a CNC turning lathe factory is the need for precision and consistency in industrial production. Traditional manual lathes rely heavily on the operator's skill, which can result in variations between parts. In industries such as automotive, aerospace, and electronics, even minor discrepancies can assembly issues or reduced product performance.

Maintaining Tight Tolerances:

CNC turning lathes are controlled by computer programs that guide the cutting tools with exact measurements. This ensures that every part produced meets precise dimensional requirements. A CNC turning lathe factory can produce components with tolerances as fine as a few microns, reducing errors that are common in manual machining.

Repetition Without Deviation:

For mass production, consistency is crucial. CNC machines can replicate the same operation hundreds or thousands of times without deviation. This consistency helps companies reduce waste and avoid costly rework, improving overall efficiency in the manufacturing process.

Complex Geometry Capabilities:

Many industrial components require intricate shapes or internal features that are difficult to achieve manually. A CNC turning lathe can perform multiple operations in a single setup, producing complex geometries with minimal human intervention. This capability solves a problem that traditional tools often struggle to address efficiently.

By improving precision and ensuring uniformity, CNC turning lathes from a CNC turning lathe factory help industries meet quality standards and customer expectations while production errors.

2. Increasing Efficiency and Reducing Production Time

Another problem solved by a CNC turning lathe factory is the need for efficient production processes. Manual machining can be time-consuming due to frequent adjustments, part measurements, and setup changes. In contrast, CNC lathes streamline operations through automation.

Automated Operations:

CNC turning lathes can operate continuously once programmed. The automation reduces the need for constant operator supervision, allowing production to continue for long shifts with minimal intervention. This increases throughput and helps meet tight deadlines.

Faster Setup and Changeover:

Traditional machines often require manual adjustments for different parts, which can slow down production. In a CNC turning lathe factory, switching between part designs involves changing the digital program rather than the physical setup. This significantly reduces downtime and improves flexibility.

Integration with Digital Systems:

CNC machines are compatible with CAD and CAM software, allowing direct translation from design to production. This integration eliminates the need for manual measurements or sketches, reducing potential errors and accelerating the manufacturing process.

Energy and Material Efficiency:

Automated control enables precise cutting paths and optimized speeds, which reduces material waste and energy consumption. By reduce scrap and resource use, CNC turning lathes contribute to more sustainable and cost-effective industrial operations.

Overall, the efficiency improvements provided by CNC turning lathes allow manufacturers to produce higher volumes of parts in less time while maintaining quality.

3. Solving Labor and Skill Limitations

Industrial production often faces challenges related to labor availability and skill levels. Skilled machinists are required to operate traditional lathes effectively, and training new operators can be time-intensive. A CNC turning lathe factory addresses these problems by simplifying machine operation and reducing dependency on manual skill.

Simplified Operation:

CNC turning lathes are programmed digitally, so operators primarily need to manage the setup, input programs, and monitor production. This reduces reliance on highly specialized manual skills, making it easier to maintain production levels even with a limited workforce.

Minimized Human Error:

Since CNC operations follow precise instructions, the likelihood of errors caused by fatigue, miscalculation, or inconsistency is greatly reduced. This ensures reliable output and reduces the need for inspection and rework.

Enhanced Safety:

Automated processes also improve workplace safety. Operators interact less directly with rotating tools, sharp edges, or heavy workpieces, the risk of accidents compared to conventional lathe operations.

Training and Skill Development:

While CNC operation still requires technical knowledge, training focuses on programming and monitoring rather than manual machining techniques. A CNC turning lathe factory can therefore adapt to workforce limitations more easily and maintain production continuity.

By addressing labor challenges, CNC turning lathes ensure that industrial production remains efficient, safe, and reliable, even in environments with workforce constraints.