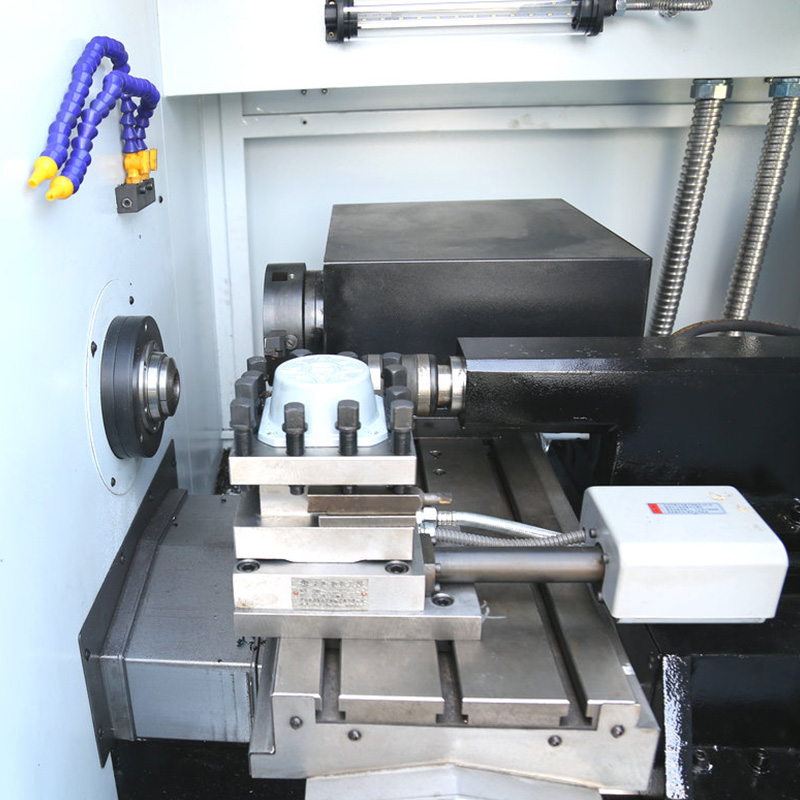

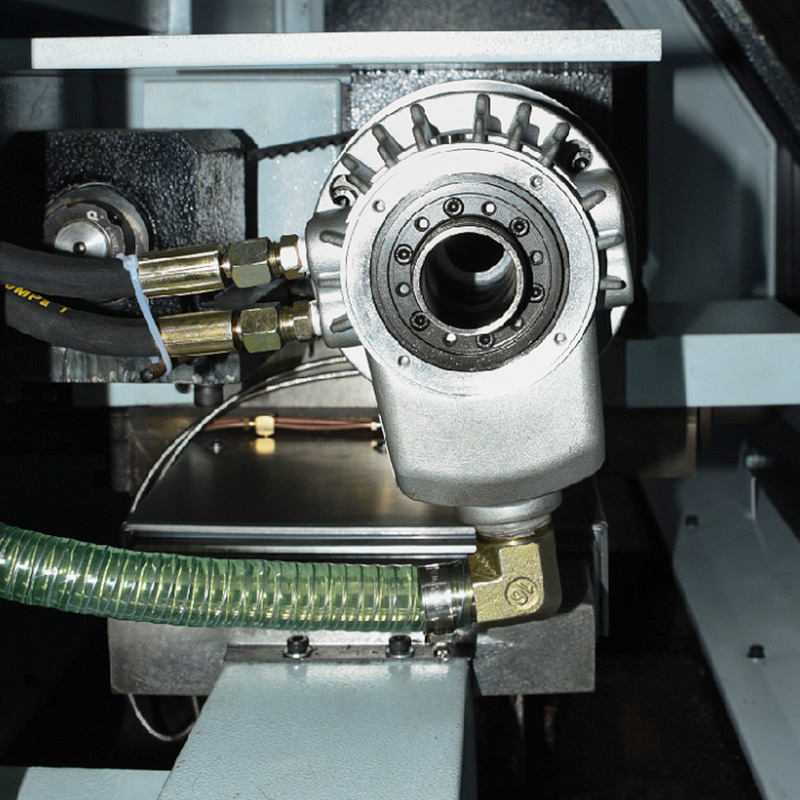

CF32 Hydraulic Clamping CNC Polygon Turning Machine

Cat:Small Polygon Lathe

CF32 hydraulic clamping CNC polygon lathe is designed for milling small and medium-sized high-precision parts, which can mill square, octagonal, hexag...

See DetailsLathe machine turning factories play a critical role in manufacturing precise metal components for various industries, including automotive, aerospace, and industrial machinery. Ensuring high-quality production requires adherence to specific standards that cover equipment operation, material selection, quality control, worker safety, and environmental compliance. A structured approach to production standards can minimize errors, improve efficiency, and maintain the reliability of finished components.

Equipment and Process Standards

Calibration and Maintenance

Lathe machines must be regularly calibrated to ensure dimensional accuracy and repeatability. Factory standards should specify periodic calibration of machine axes, spindle alignment, and tool holders. In practice, automotive parts manufacturers often implement monthly or quarterly checks to verify tolerances and ensure machines meet specified precision levels. Regular maintenance schedules, including lubrication and inspection of bearings and lead screws, are also necessary to maintain consistent performance.

Standard Operating Procedures (SOPs)

SOPs outline how operators should perform turning tasks, including machine setup, tool installation, speed and feed selection, and coolant use. For example, precision component manufacturers create SOPs detailing the sequence of operations for machining engine components to avoid errors and ensure uniformity. SOPs help reduce variability among operators and provide a baseline for training new personnel.

Process Monitoring and Control

Continuous monitoring of cutting parameters, vibration, and surface finish is essential. Factories can implement digital sensors or machine tools with built-in monitoring systems to ensure operations remain within defined limits. For example, a factory producing bearing housings may track spindle vibration and tool wear to prevent deviations that could compromise component performance. Process monitoring ensures timely adjustments and reduces waste.

Material and Tooling Standards

Material Selection and Traceability

Lathe machine turning often involves metals such as steel, aluminum, and brass. Factories should adhere to standards for material grade, mechanical properties, and traceability. Real-life examples include aerospace component manufacturers, where specific alloy grades must meet defined tensile strength, hardness, and chemical composition. Maintaining material certificates and batch tracking ensures that only verified materials enter production.

Tooling Standards

Cutting tools, inserts, and tool holders should comply with standardized dimensions, coatings, and performance specifications. Using substandard tools can poor surface finish, dimensional inaccuracies, and reduced machine life. For instance, factories producing automotive transmission components may specify carbide inserts with defined geometries and coating types to maintain uniform cutting conditions.

Storage and Handling

Proper storage of materials and tooling reduces contamination and damage. Metal bars, rods, and sheets should be organized and protected from moisture and dust. Similarly, cutting tools should be stored in designated trays or cabinets to prevent chipping or corrosion. This attention to handling supports consistent production quality.

Quality Control and Inspection Standards

Dimensional Inspection

Lathe factories must implement inspection procedures to verify that components meet dimensional tolerances. Tools such as micrometers, calipers, coordinate measuring machines (CMMs), and gauges are commonly used. For example, precision shaft manufacturers perform in-process checks and final inspection using CMMs to ensure parts conform to design specifications.

Surface Finish and Visual Inspection

Surface roughness, burrs, and scratches can affect component performance. Factories should use standardized methods for measuring surface finish and perform visual inspections at different stages of production. In practice, medical device component manufacturers maintain surface roughness within specific micrometer limits to ensure proper assembly and function.

Documentation and Record-Keeping

Maintaining detailed records of inspections, deviations, and corrective actions is crucial. These records support traceability, quality audits, and continuous improvement. For instance, aerospace factories maintain inspection logs for every batch of machined components to comply with regulatory and customer requirements.

Occupational Safety and Environmental Standards

Worker Safety

Factories must adhere to occupational safety standards, including the use of personal protective equipment (PPE), safe handling of rotating machinery, and proper training for operators. Real-life examples include factories requiring safety glasses, gloves, and ear protection during high-speed turning operations. Lockout-tagout procedures should also be followed to prevent accidents during machine maintenance.

Coolant and Lubricant Management

Proper handling and disposal of cutting fluids and lubricants are essential to prevent workplace hazards and contamination. Factories should follow guidelines for storage, recycling, and disposal of fluids. In high-volume machining plants, coolant filtration systems are used to remove metal chips and maintain fluid quality.

Environmental Compliance

Lathe factories should comply with local regulations regarding waste management, air emissions, and noise control. For instance, metal machining plants may use chip collectors, ventilation systems, and noise-dampening enclosures to minimize environmental impact. Adherence to these standards ensures sustainable production practices.