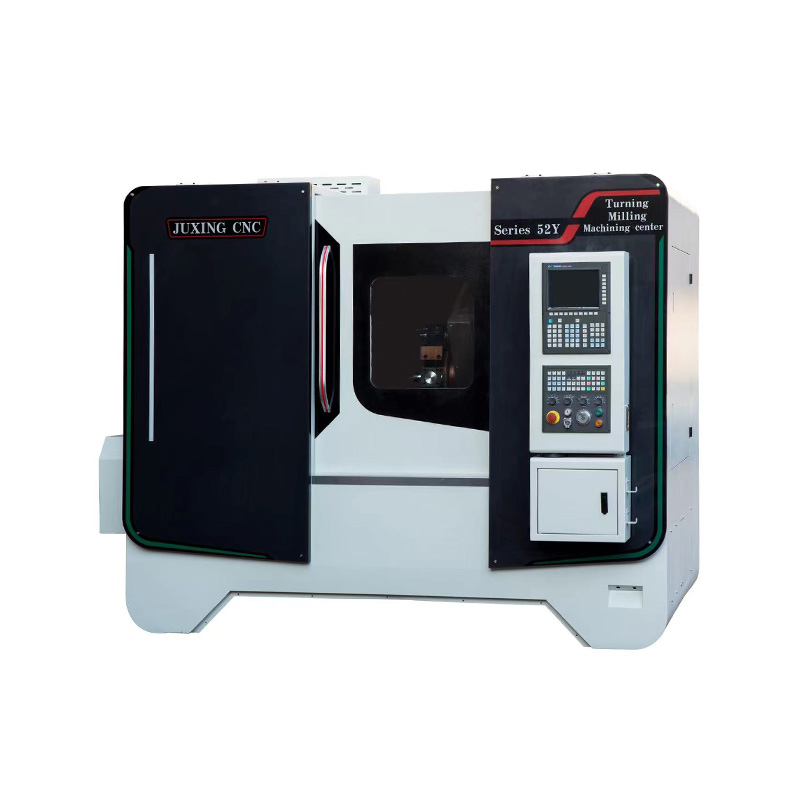

CF60 CNC Polygon Lathe

Cat:High Rigidity Polygon Lathe

The CF60 CNC Polygon Lathe is a highly efficient and versatile machine tool designed for small to medium-sized precision parts milling. It is capable ...

See DetailsCNC milling machines factory have revolutionized the manufacturing industry by offering a high level of precision, automation, and efficiency. Used extensively in industries such as aerospace, automotive, and metalworking, CNC milling machines allow manufacturers to create complex parts with unparalleled accuracy. These machines operate by moving a rotating cutter along multiple axes, shaping a workpiece to meet specific design requirements.

1. What is a CNC Milling Machine?

The process of milling involves a cutter that rotates at high speeds to remove material from the workpiece. The workpiece is typically held in place by a vice or clamping system. The cutting tool moves along the X, Y, and Z axes, removing material layer by layer to shape the workpiece into the desired form.

2. Key Components of a CNC Milling Machine

A CNC milling machine is composed of several components that work together to ensure precise and efficient operation. The main components include the following:

a. The Control System

The control system is the heart of a CNC milling machine. It consists of a computer and software that reads the G-code or other programming languages to control the machine's operations. The G-code provides specific instructions for the machine, such as the tool's movement, speed, and direction. CNC systems allow operators to input complex design data, enabling the machine to execute highly detailed tasks with precision.

Advantages:

Allows for easy adjustments and modifications to designs.

Ensures precise replication of parts based on the input program.

Facilitates automated operation, reducing human error and labor costs.

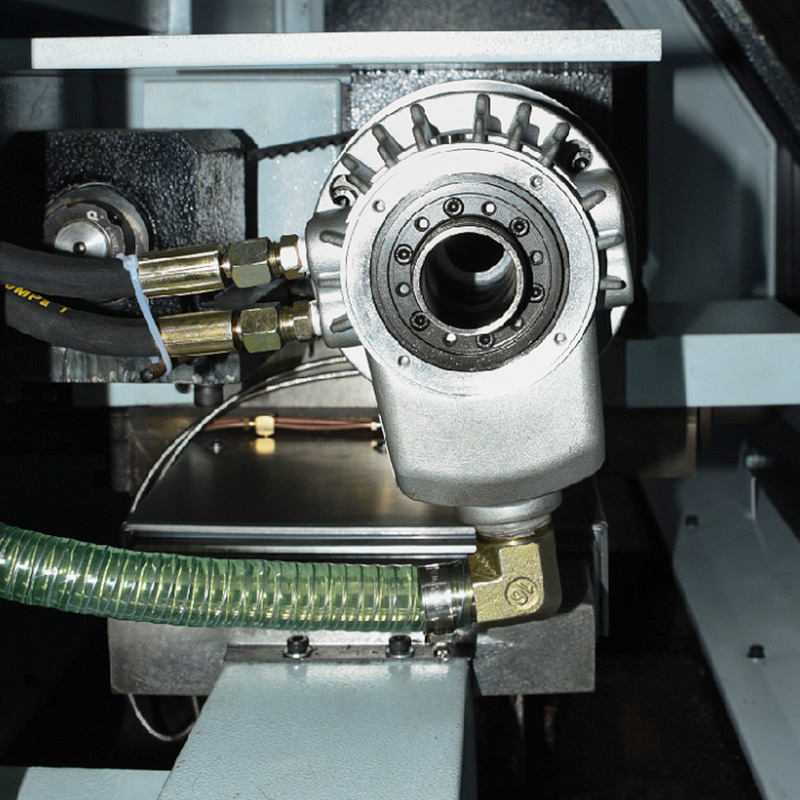

b. The Spindle

The spindle is a crucial part of the CNC milling machine responsible for holding and rotating the cutting tool. It rotates at high speeds, allowing the cutting tool to remove material from the workpiece. The spindle’s speed and torque are adjustable, depending on the material being worked with and the type of cut required. High-speed spindles are often used for cutting hard materials, while slower speeds are used for softer materials.

Advantages:

High-speed rotation improves cutting efficiency and accuracy.

Adjustable speed allows for versatility in machining different materials.

Provides smooth and consistent cutting operations.

c. The Table

The table of a CNC milling machine is where the workpiece is mounted during the machining process. It typically moves along the X and Y axes, allowing the cutter to reach different points on the workpiece. In more advanced machines, the table can be rotated or tilted, providing additional flexibility for multi-axis milling operations.

Advantages:

Provides a stable platform for holding the workpiece during milling.

Some machines feature rotary tables for advanced multi-axis machining.

Adjustable to accommodate various sizes and shapes of workpieces.

d. The Axis System

CNC milling machines typically have three, four, or five axes, depending on the machine’s capabilities. The X, Y, and Z axes correspond to the horizontal and vertical movement of the table and spindle, respectively. In more advanced machines, additional rotary axes (A and B) may be present to allow for more complex movements and the ability to machine parts at multiple angles in a single operation.

Advantages:

Multi-axis systems allow for complex shapes and intricate designs.

Provides flexibility in machining parts from multiple angles, reducing the need for re-positioning.

Offers high precision and consistency in part production.

e. The Tool Holder and Cutting Tools

The tool holder is responsible for securely holding the cutting tool in place during the milling process. The cutting tools themselves come in a variety of shapes and sizes, depending on the type of milling operation. Common types of cutting tools include end mills, face mills, and drill bits. These tools are designed for different tasks, such as rough cutting, finishing, or drilling holes.

Advantages:

Tool holders ensure that the cutting tools remain stable and accurate during the machining process.

A variety of tools are available to cater to different materials and machining needs.

High-quality cutting tools better finish quality and reduced tool wear.

f. The Coolant System

Milling processes can generate significant heat due to friction between the cutting tool and the workpiece. The coolant system is designed to cool the cutting tool and workpiece, preventing overheating and ensuring the longevity of both. Coolants also help to wash away chips and debris produced during the cutting process.

Advantages:

Prevents overheating, which can cause damage to both tools and parts.

Helps improve cutting efficiency by reducing friction.

Ensures a clean and precise finish on the workpiece.

3. Efficiency of CNC Milling Machines

The efficiency of CNC milling machines is determined by several factors, including speed, precision, automation, and material handling. Here’s how these elements contribute to overall efficiency:

a. Speed and Throughput

CNC milling machines are capable of high-speed operations, which can significantly improve production rates. The faster the machine can process materials, the more parts can be produced within a given time. Additionally, CNC milling machines can operate 24/7 with minimal human intervention, providing continuous production capabilities.

Advantages:

Shorter production times increased throughput.

The ability to operate without rest improves overall productivity.

High-speed operations reduce the overall manufacturing cost per unit.

b. Precision and Accuracy

One of the primary benefits of CNC milling machines is their ability to maintain high levels of precision and accuracy. Computer-controlled operations eliminate human error, ensuring that each part is produced to the exact specifications. This is particularly important in industries such as aerospace and medical device manufacturing, where precision is critical.

Advantages:

Ensures that parts meet exact specifications and tolerances.

Reduces the need for rework or scrap due to faulty parts.

Provides consistency across production runs, essential for mass production.