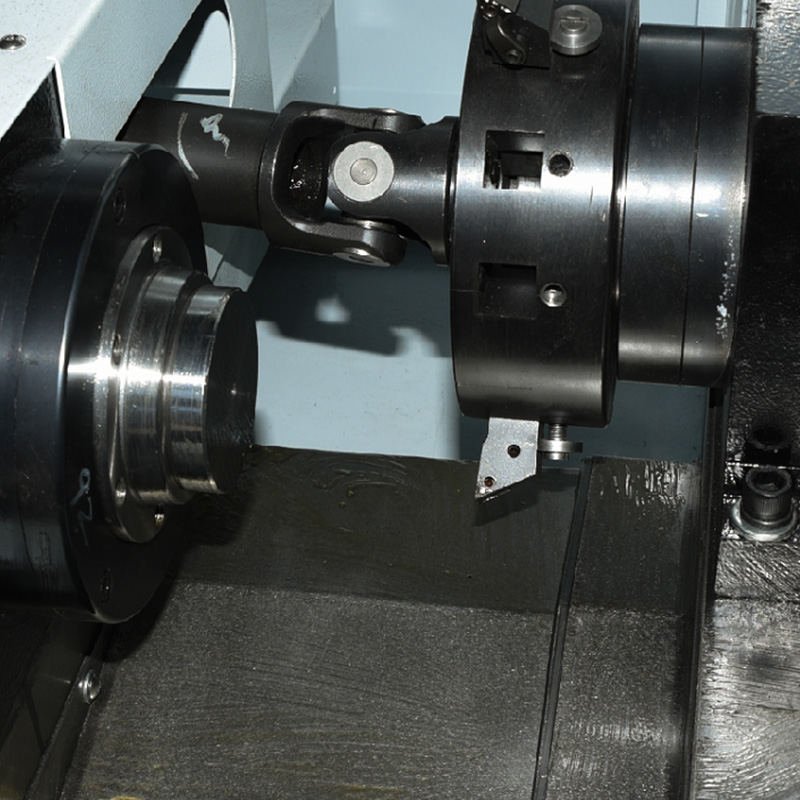

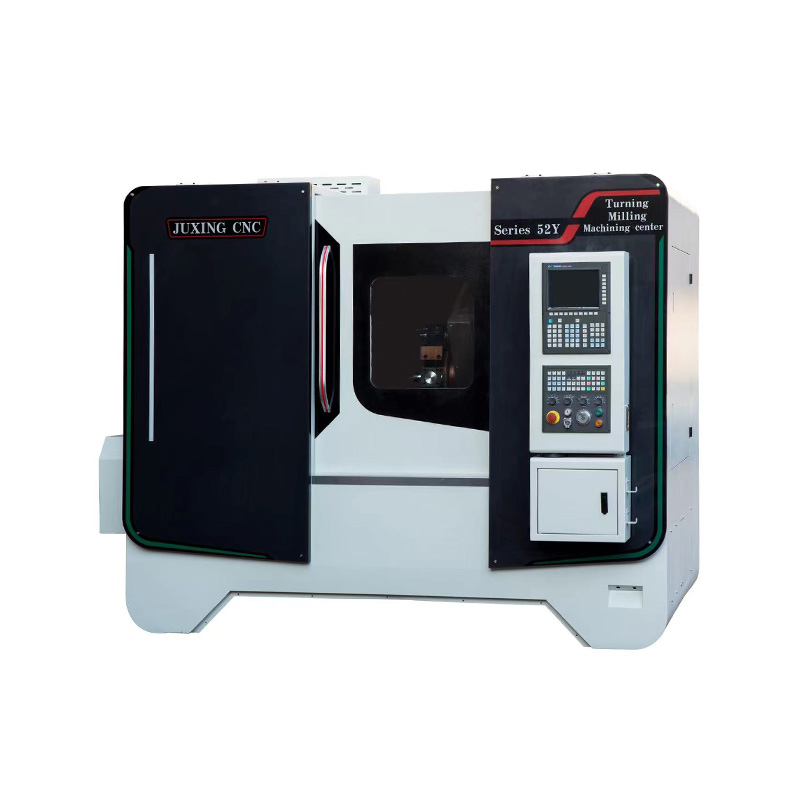

CF32 Hydraulic Clamping CNC Polygon Turning Machine

Cat:Small Polygon Lathe

CF32 hydraulic clamping CNC polygon lathe is designed for milling small and medium-sized high-precision parts, which can mill square, octagonal, hexag...

See DetailsCNC lathe machining factory has become a cornerstone in modern manufacturing, offering precision, efficiency, and flexibility for producing cylindrical or complex components. Unlike manual lathes, CNC (Computer Numerical Control) lathes are programmed to execute precise operations automatically, reducing human error and increasing production consistency.

Key Advantages of CNC Lathe Machining

CNC lathe machining offers multiple benefits that make it a preferred choice in industries ranging from automotive and aerospace to electronics and medical device manufacturing.

High precision and accuracy: CNC lathes are capable of producing parts with tight tolerances, often within microns. This precision is critical for components requiring exact dimensions, consistent finishes, and reliable functionality.

Consistency and repeatability: Once programmed, CNC lathes can produce identical parts repeatedly without variation. This consistency is especially beneficial for mass production, ensuring that every component meets quality standards.

Reduced labor requirements: CNC lathes automate complex operations that would otherwise require skilled operators to execute manually. This reduces labor costs and minimizes the risk of human error during production.

Versatility: CNC lathes can perform multiple operations such as turning, facing, threading, drilling, and grooving in a single setup. This flexibility allows manufacturers to produce a wide range of components with minimal retooling.

Efficient material utilization: CNC lathes optimize cutting paths and operations, reducing material waste and improving production efficiency. This is particularly important when working with costly metals or specialty alloys.

Enhanced safety: Automated operation reduces the need for operators to be in close contact with moving parts, the risk of accidents and improving workplace safety.

These advantages make CNC lathe machining a reliable, efficient, and practical choice for modern manufacturing environments.

Functional Features

The performance of a CNC lathe depends on its design, programming capabilities, and operational features.

Computer-controlled operations: CNC lathes use software to control spindle speed, feed rate, tool paths, and cutting depth. This allows precise and complex operations that would be challenging to achieve manually.

Tool turret and automatic tool changer: Many CNC lathes feature a turret or automatic tool changer that holds multiple cutting tools. This enables sequential operations without manual intervention, reducing setup time and improving productivity.

Spindle speed and torque control: Adjustable spindle speeds and torque settings allow the machine to work with a variety of materials, from soft plastics to hardened steel, ensuring cutting performance.

Axis movement: CNC lathes often operate along multiple axes, including X, Z, and sometimes Y axes. Multi-axis movement enhances flexibility, allowing for more complex geometries and intricate parts.

User-friendly interface: Modern CNC lathes feature intuitive control panels or touchscreen interfaces, simplifying programming and monitoring for operators of varying experience levels.

High-quality construction: Precision engineering, rigid frames, and vibration-dampening designs contribute to consistent machining quality and long machine life.

These features combine to make CNC lathes capable of handling complex, high-precision tasks efficiently.

Performance Considerations

When evaluating CNC lathe machining, several performance factors influence its suitability for specific applications.

Production speed: CNC lathes are generally faster than manual lathes due to automated operations and optimized tool paths. This improves throughput and reduces time for manufacturing projects.

Accuracy and surface finish: CNC machining delivers consistent tolerances and high-quality surface finishes. Precision controls and proper tool selection minimize errors and defects.

Material compatibility: CNC lathes can machine a wide range of materials, including metals, plastics, composites, and specialty alloys. The machine’s spindle power and tool configuration determine performance for different material types.

Maintenance and reliability: CNC lathes require regular maintenance, such as lubrication, calibration, and software updates. High-quality machines with durable components ensure long-term reliability and consistent output.