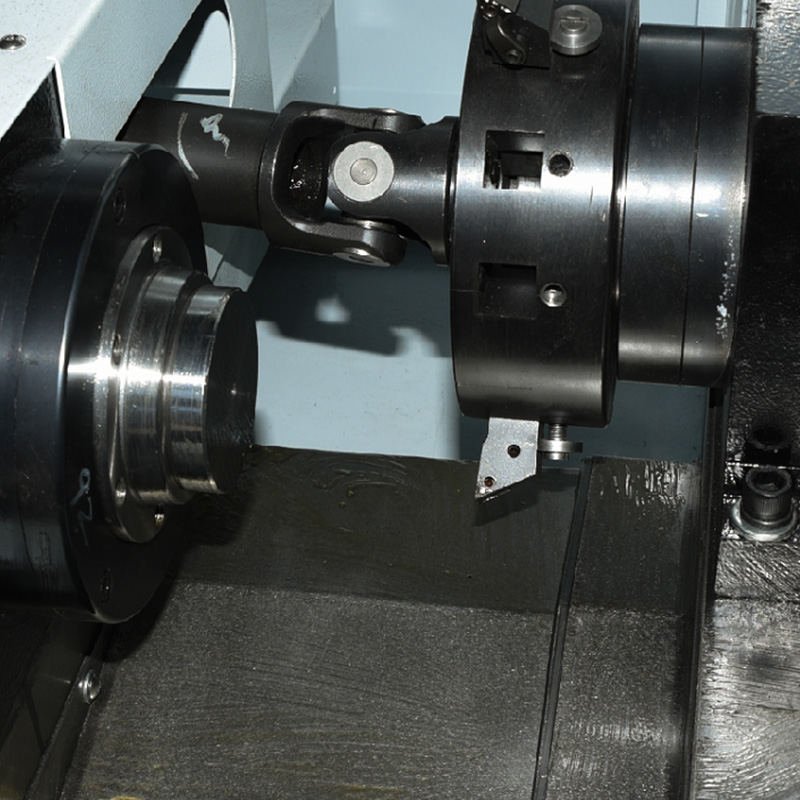

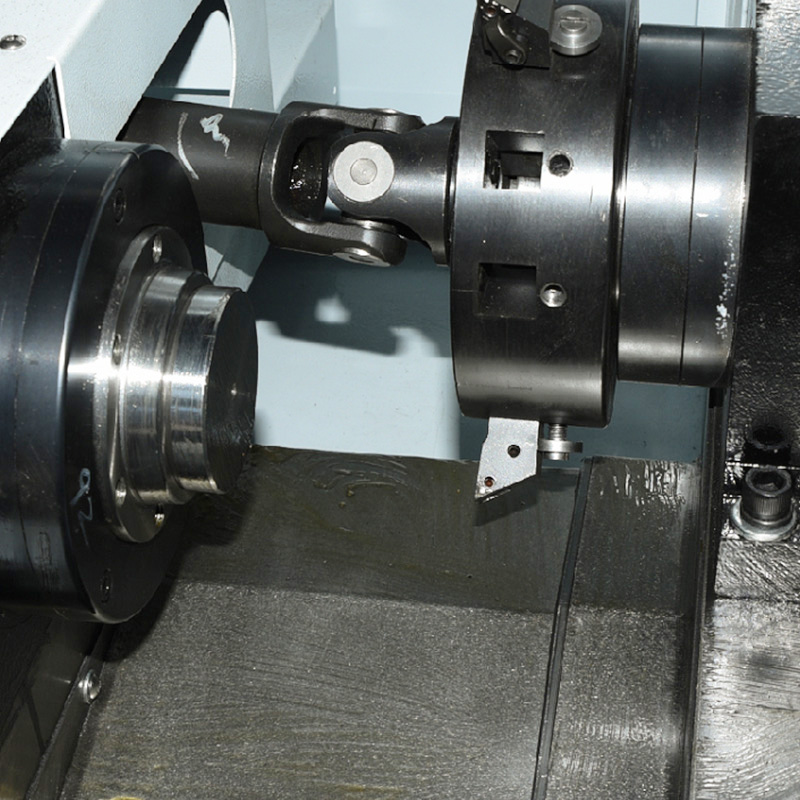

CF32 Hydraulic Clamping CNC Polygon Turning Machine

Cat:Small Polygon Lathe

CF32 hydraulic clamping CNC polygon lathe is designed for milling small and medium-sized high-precision parts, which can mill square, octagonal, hexag...

See DetailsMilling machines factory are essential tools in manufacturing, metalworking, and fabrication. They allow for precise cutting, shaping, and drilling of materials, offering versatility for both industrial and workshop applications. Selecting the right milling machine requires understanding the various types available, their specific features, and the requirements of the tasks to be performed.

Types of Milling Machines

Milling machines can be classified according to their configuration, axis movement, and purpose. Each type serves different manufacturing needs.

Vertical milling machines: In vertical milling machines, the spindle is oriented vertically, allowing the cutting tool to move up and down. This design is suitable for tasks such as slotting, drilling, and precision contouring. Vertical milling machines are widely used due to their versatility and ease of operation.

Horizontal milling machines: In these machines, the spindle is positioned horizontally, enabling the use of different types of cutting tools such as side-and-face cutters. Horizontal milling machines are ideal for cutting deep grooves, heavy-duty material removal, and machining large workpieces. They provide stability and efficiency for extensive production tasks.

Universal milling machines: Universal machines combine features of both vertical and horizontal types, allowing the spindle and table to be adjusted for multiple angles and orientations. This type is suitable for versatile operations, including complex cutting and multi-angle machining.

CNC milling machines: Computer Numerical Control (CNC) milling machines use programmable software to control movement and operations. They offer high precision, repeatability, and automation, making them suitable for high-volume production, complex parts, and tasks requiring tight tolerances. CNC machines can be vertical, horizontal, or hybrid in configuration.

Bed-type milling machines: These machines feature a fixed table with a movable spindle or cutter head. They are robust and capable of handling heavy workpieces. Bed-type machines are suitable for large-scale machining and industrial applications.

Knee-type milling machines: Knee-type machines have a vertically adjustable table supported by a knee. This design allows for greater flexibility in vertical positioning and is commonly used in workshops for small to medium-sized parts.

Understanding these types helps manufacturers and hobbyists choose a machine that matches their production needs and workspace requirements.

Features and Advantages

The effectiveness of a milling machine is influenced by its construction, operational features, and control systems.

Axis movement: Milling machines can have different axis capabilities, such as 3-axis, 4-axis, or 5-axis machines. More axes provide increased flexibility, allowing for complex cuts and multi-directional operations.

Spindle speed and power: Adjustable spindle speed ensures proper cutting performance for various materials, including metals, plastics, and wood. Machines with higher power and torque handle tougher materials more efficiently.

Table size and travel: Larger tables provide the ability to work on bigger pieces and accommodate fixtures. The travel distance of the table in the X, Y, and Z directions determines the range of work the machine can handle.

Precision and repeatability: High-quality milling machines maintain accurate positioning and consistent cuts, which is essential for producing precise components and reducing material waste.

Versatility: Machines with adjustable spindle orientation, removable heads, or modular attachments can perform a wider variety of operations, from drilling to contouring and gear cutting.

These features enhance the machine’s utility, making it adaptable for both simple and complex manufacturing tasks.

How to Choose the Right Milling Machine

Selecting a milling machine depends on several factors, including the type of work, production volume, and user expertise.

Material and workpiece size: For small-scale work or lightweight materials, vertical or knee-type machines are often sufficient. For heavy-duty tasks and large workpieces, horizontal or bed-type machines are more appropriate.

Precision requirements: If high precision is needed, such as in aerospace or automotive component production, CNC machines offer the accuracy and repeatability required.

Production volume: Manual milling machines are suitable for low-volume or workshop tasks. For high-volume production, CNC machines improve efficiency and reduce labor costs.

Available space: Consider the size of the machine relative to the workspace. Large bed-type or horizontal machines may require dedicated floor space and foundation support.

Budget considerations: CNC and universal machines typically involve higher initial investment but offer long-term productivity benefits. Manual machines have lower upfront costs and are easier to maintain for basic operations.