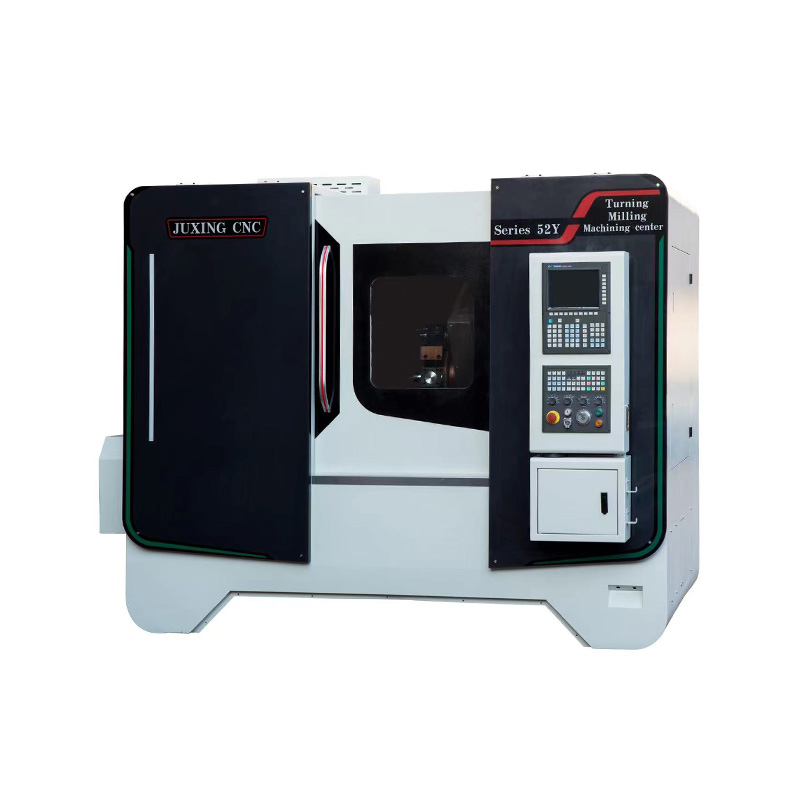

CF40 Automatic CNC Polygon Turning Machine Lathe

Cat:Small Polygon Lathe

The CF40 Automatic CNC Polygon Turning Machine Lathe is specifically designed for small to medium-sized, high-precision parts milling, enabling the ma...

See DetailsCNC turning lathes factory are essential machines in modern manufacturing, known for their precision, speed, and versatility. These machines are used to shape a wide range of materials into cylindrical parts through the process of turning. Unlike traditional lathes, which require manual input, CNC (Computer Numerical Control) turning lathes use pre-programmed software to automate the turning process, offering significant improvements in accuracy and efficiency.

A CNC turning lathe is a machine tool used for producing cylindrical parts by rotating the workpiece against a cutting tool. This rotation enables the cutting tool to remove material from the surface, allowing the machine to create complex shapes with high precision. The “CNC” aspect refers to the use of computerized control systems, which allow for highly automated and precise control of the machine's movements.

CNC turning lathes are often used to produce parts such as shafts, spindles, bushings, and other round components. The automation and flexibility of these machines make them ideal for mass production as well as small-batch production, offering benefits like reduced setup times, improved consistency, and higher productivity.

Key Design Considerations for CNC Turning Lathes

Several important factors are taken into account during the design of CNC turning lathes. These factors influence the machine’s performance, accuracy, and versatility in different manufacturing environments. Below are the main design considerations:

1. Accuracy and Precision

One of the primary reasons CNC turning lathes are so popular is their ability to achieve high levels of precision. The design of the machine must ensure that all components, such as the spindle, tool holders, and linear guides, are rigid and capable of maintaining tight tolerances. The stability of the machine is critical for ensuring the consistent quality of parts.

Linear Guides and Ball Screws: These components help ensure that the movement of the cutting tool and workpiece is smooth and precise.

Spindle Quality: The spindle must be designed to run at high speeds with minimal vibration, which helps achieve accurate cuts.

Thermal Stability: CNC turning lathes are designed to minimize thermal effects that can cause dimensional changes. This ensures that the machine maintains accuracy throughout its operation, even during long production runs.

2. Power and Speed

The power and speed of a CNC turning lathe are determined by the motor and drive system. A high-performance motor is needed to provide sufficient torque to rotate the workpiece at high speeds, allowing for faster material removal and improved cycle times.

Variable Speed Control: CNC turning lathes are typically equipped with a variable speed drive system, allowing operators to adjust the speed of the spindle to suit different materials and cutting operations.

High Torque Motors: High torque motors ensure that the machine can handle heavier workpieces and tougher materials without compromising performance.

Rapid Tool Changes: Many modern CNC turning lathes feature automatic tool changers, which help reduce downtime and increase efficiency.

3. Workholding System

A key design feature of any CNC turning lathe is its workholding system, which securely holds the workpiece during the turning process. This system must be designed to handle various types of workpieces while ensuring minimal deformation or vibration during cutting.

Chucks and Collets: The workpiece is often held in a chuck or collet, which can be manually or automatically clamped onto the material.

Hydraulic vs. Manual Clamps: CNC turning lathes can be designed with either hydraulic or manual workholding systems. Hydraulic systems offer faster clamping and higher clamping force, while manual systems are more affordable and simpler to operate.

Customization: Workholding systems can be customized to accommodate various workpiece sizes and geometries, ensuring flexibility in the types of parts the machine can produce.

4. Tooling and Tool Change Mechanism

Tooling is a vital component of CNC turning lathes, and the design of the tool change mechanism plays a significant role in the machine’s overall performance and efficiency. Tool changes must be fast, precise, and reliable to ensure smooth operation during production.

Automatic Tool Changers (ATC): Many CNC turning lathes are equipped with an automatic tool changer that can load and unload tools as needed during the machining process. This reduces the need for manual intervention and minimizes production downtime.

Tool Holders and Tool Blocks: The design of the tool holder should allow for precise tool positioning and secure tool retention during operation.

Multi-tool Capabilities: Some CNC turning lathes are designed with the ability to use multiple tools simultaneously or sequentially, enabling complex machining operations like milling and drilling in addition to turning.