The CNC machine tool factory represents a significant advancement in manufacturing technology, enabling precise, automated control of machining operations. While these systems enhance productivity and consistency, their implementation and operation are not without challenges. The problems associated with CNC machine tools can be analyzed systematically, focusing on their financial implications, technical and operational complexities, human resource dependencies, and safety considerations.

I. Financial and Economic Challenges

The economic impact of CNC machinery extends beyond the initial purchase price, encompassing a range of ongoing and hidden costs.

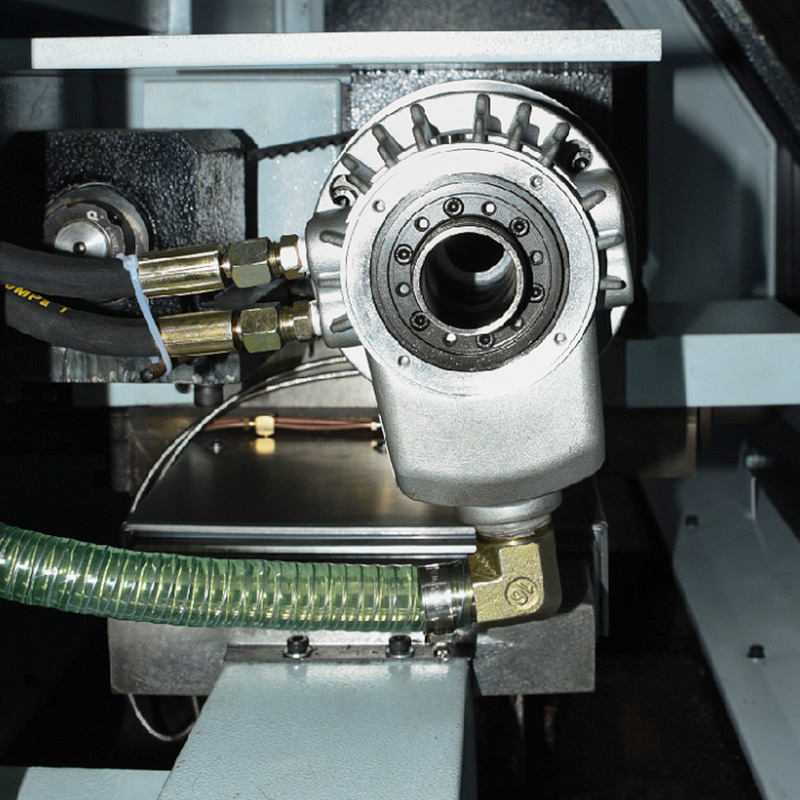

- High Capital Investment: The acquisition cost of a CNC machine tool is substantially higher than that of conventional manual machinery. This includes not only the base machine but also essential peripherals such as tooling, workholding fixtures, and coolant systems. For small and medium-sized enterprises, this initial outlay can represent a significant financial commitment, requiring careful justification through projected returns on investment.

- Substantial Operating and Maintenance Costs: Operating a CNC machine incurs recurring expenses. These include the cost of cutting tools, which wear out and must be replaced regularly, and electricity, as CNC machines are continuous power consumers. Furthermore, maintenance is not optional; it requires scheduled servicing by specialized technicians, contracts for software updates, and the potential need for expensive spare parts. A failure to maintain the equipment properly can more costly breakdowns and production stoppages.

- Economic Inflexibility in Low-Volume Production: The efficiency of CNC machining is apparent in medium to high-volume production runs where the programming and setup time can be amortized over many units. For prototyping or very small batch jobs, the time and cost required to program and set up the machine can make the process less economical compared to manual machining or alternative manufacturing methods.

II. Technical and Operational Complexities

The sophisticated nature of CNC technology introduces a set of technical challenges that can affect workflow and output.

- Programming and Software Dependency: Every part machined on a CNC requires a meticulously written program. Generating this code requires skilled programmers and can be time-consuming. Any error in the code, whether in geometry, tool path, or speed and feed settings, can a catastrophic collision, damaging the machine, ruining the workpiece, and potentially causing injury. The entire process is dependent on stable and compatible software systems.

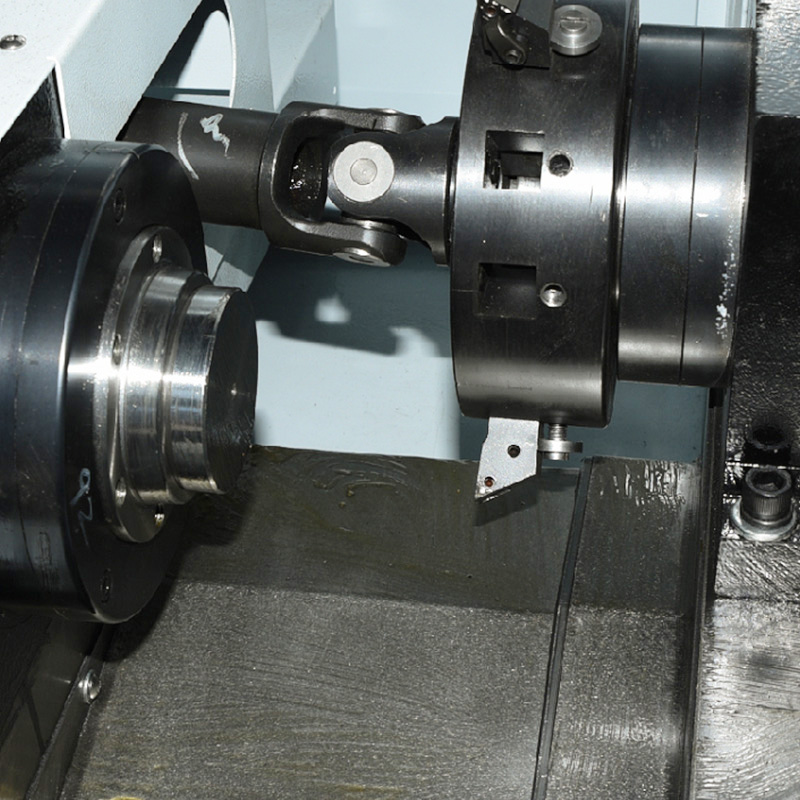

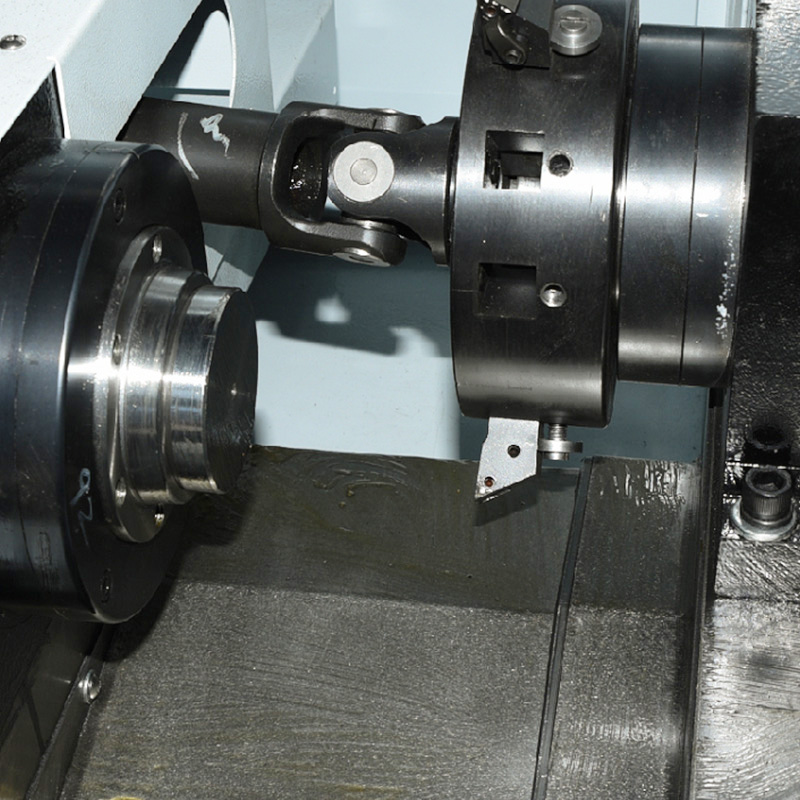

- Preventable Technical Failures: CNC systems are complex integrations of mechanical, electrical, and software components. This complexity creates multiple potential points of failure. These can range from mechanical issues like ball screw wear or spindle bearing failure to electronic problems in servo motors or control boards. Sensor malfunctions can provide incorrect feedback, process errors. Diagnosing and repairing these failures often requires specialized expertise and can result in significant machine downtime.

- Limitations in Material and Design: While versatile, CNC machining has inherent constraints. It is a subtractive process, meaning material is removed from a solid block to create a part. This can significant material waste, especially for parts with complex geometries. Furthermore, certain internal geometries or undercuts may be impossible to produce with standard CNC milling or turning, limiting design freedom compared to additive manufacturing processes like 3D printing.

III. Human Resource and Management Issues

The operation of a CNC-centric workshop creates specific demands on the workforce and management structure.

- Dependence on Skilled Personnel: The shift from manual to CNC machining transforms the role of the machinist from an operator to a programmer, set-up technician, and supervisor. This requires a different and often more advanced skill set, including the ability to read complex blueprints, understand G-code, and operate computer-aided manufacturing (CAM) software. There is a documented shortage of individuals with these hybrid skills, making recruitment and retention a challenge.

- Workforce Adaptation and Cultural Resistance: The introduction of automated technology can create apprehension among traditional machinists. Some may perceive CNC machines as a threat to their jobs or may be resistant to learning new computer-based skills. Managing this transition requires effective change management, including transparent communication and comprehensive training programs, to ensure workforce buy-in and a smooth integration of the new technology.