The basic working principle of a gang type CNC lathe revolves around its ability to hold several tools in a fixed position and execute multiple operations in a sequence. Here's a step-by-step breakdown of how it works:

Tool Arrangement: The gang type CNC lathe uses a gang plate (a fixed tool holder) where multiple tools—such as turning tools, drills, and taps—are mounted. These tools are arranged close together to minimize the distance between operations.

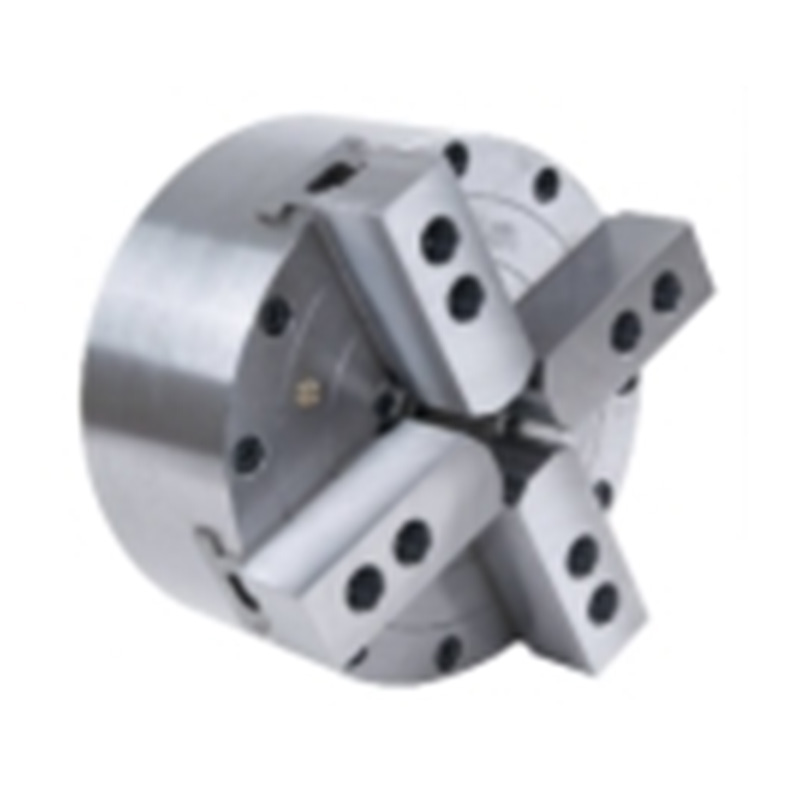

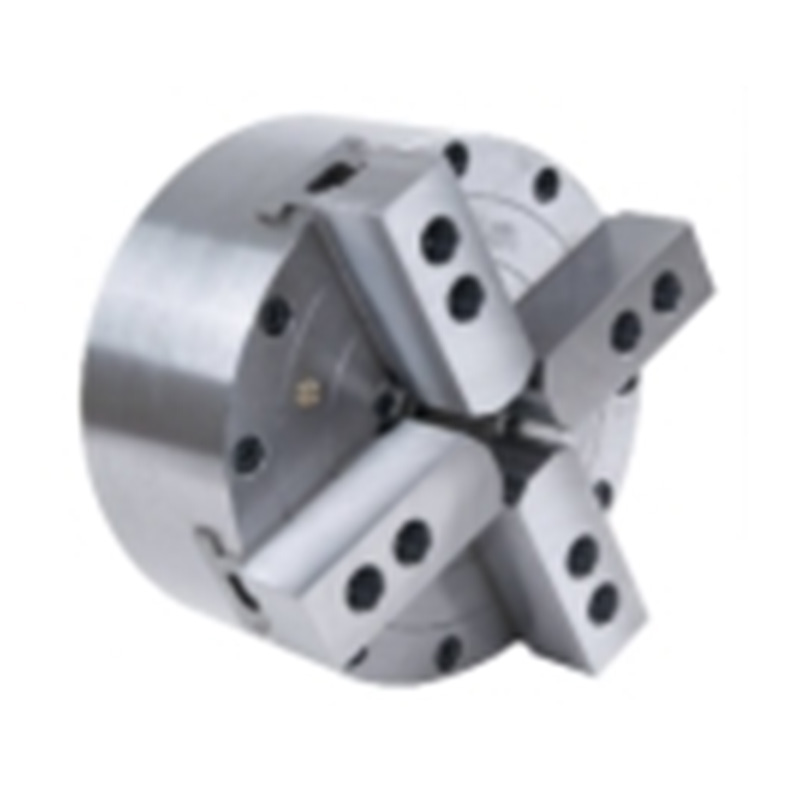

Workpiece Placement: The workpiece is mounted onto the spindle of the lathe. The spindle rotates the part, and as the tools are brought into contact with the workpiece, material is removed in the desired shape.

Machining Process: With a gang type CNC lathe, the machine can perform different operations in a single setup. For example, one tool may turn the outside diameter, while another drills holes and a third performs threading. The program controls the sequence of operations and ensures that the tools engage at the right moment.

Tooling Flexibility: Because the tools are mounted on the gang plate, they do not need to be indexed like on turret-based machines, allowing for faster tool changes and more efficient machining. The flexibility of the setup makes it possible to carry out complex tasks with minimal downtime.

CNC Programming: The machine's CNC system is programmed with the necessary instructions for each tool and operation. This program coordinates the movement of the tools, ensuring that each step in the machining process is executed in the correct order.

Gang type CNC lathes offer several advantages over traditional turret-based lathes and other machining methods. These advantages contribute to their widespread use in high-volume production settings.

High-Speed Machining: One of the main benefits of the gang type CNC lathe is its ability to perform operations quickly. The fixed tool arrangement eliminates the need for tool changes and indexing, reducing cycle times. This makes gang type lathes ideal for high-speed, high-precision operations.

Precision and Accuracy: The arrangement of tools in a gang type CNC lathe ensures minimal tool change time and error. Since all tools are mounted on the same plate and do not need to rotate or shift, the workpiece is machined with exceptional precision, making these machines ideal for producing tight-tolerance parts.

Reduced Setup Time: Traditional turret lathes require significant setup time to change and align tools. With a gang type CNC lathe, the tools are fixed in place, and once the machine is programmed, it can perform the required operations without any additional adjustments, thus reducing setup time.

Space Efficiency: Gang type CNC lathes are more compact than turret-based machines. Since the tool holders are placed on a fixed plate, the overall size of the machine is smaller, making it more suitable for environments with limited space.

Cost-Effective for Small to Medium Production Runs: The efficiency and speed of gang type CNC lathes make them cost-effective for producing small to medium batches of parts. The ability to handle multiple operations in one setup reduces labor and tooling costs, making it ideal for manufacturers who require fast production without sacrificing quality.

Flexibility: Gang type CNC lathes are versatile, capable of handling a variety of materials such as steel, aluminum, brass, and plastics. They are used in industries ranging from automotive to medical device manufacturing, offering a wide range of applications.

English

English 中文简体

中文简体 русский

русский