CF60 CNC Polygon Lathe

Cat:High Rigidity Polygon Lathe

The CF60 CNC Polygon Lathe is a highly efficient and versatile machine tool designed for small to medium-sized precision parts milling. It is capable ...

See DetailsLinear guide CNC machines are integral to modern manufacturing and machining processes, playing a key role in industries that demand high precision, durability, and efficiency. These machines combine the capabilities of Computer Numerical Control (CNC) technology with the precise motion control provided by linear guides. Linear guides allow for smooth and accurate movement of machine components, making them ideal for applications that require high-quality machining.

Linear guide CNC machines are CNC machines equipped with linear guide systems that provide precise linear motion. A linear guide is a mechanical system designed to facilitate smooth, frictionless movement along a linear path, using rolling elements like balls or rollers. These guides are typically mounted along the machine's axes and support moving parts such as the machine's bed, table, or spindle.

In CNC machines, linear guides work alongside motors, ballscrews, and control systems to ensure the accurate and repeatable movement of machine components. This precision motion is essential in applications where small tolerances and fine details are critical.

Linear guide CNC machines consist of several components that work in unison to achieve precise motion. The key elements of these systems include:

a) Linear Guide Rails:

The rails are the foundation of the linear guide system, providing the track along which the moving components travel. They are usually made of high-strength steel or other durable materials to ensure longevity and smooth operation.

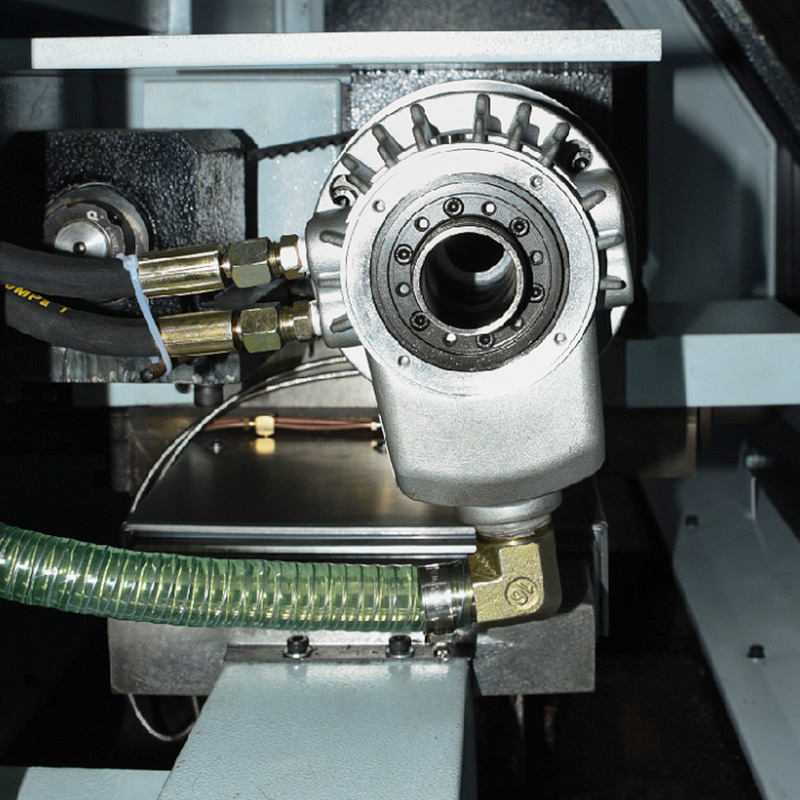

b) Linear Bearings:

These are the moving components that roll along the guide rails, allowing for frictionless movement. Linear bearings can be ball-type or roller-type, each offering different advantages in terms of load capacity, speed, and accuracy.

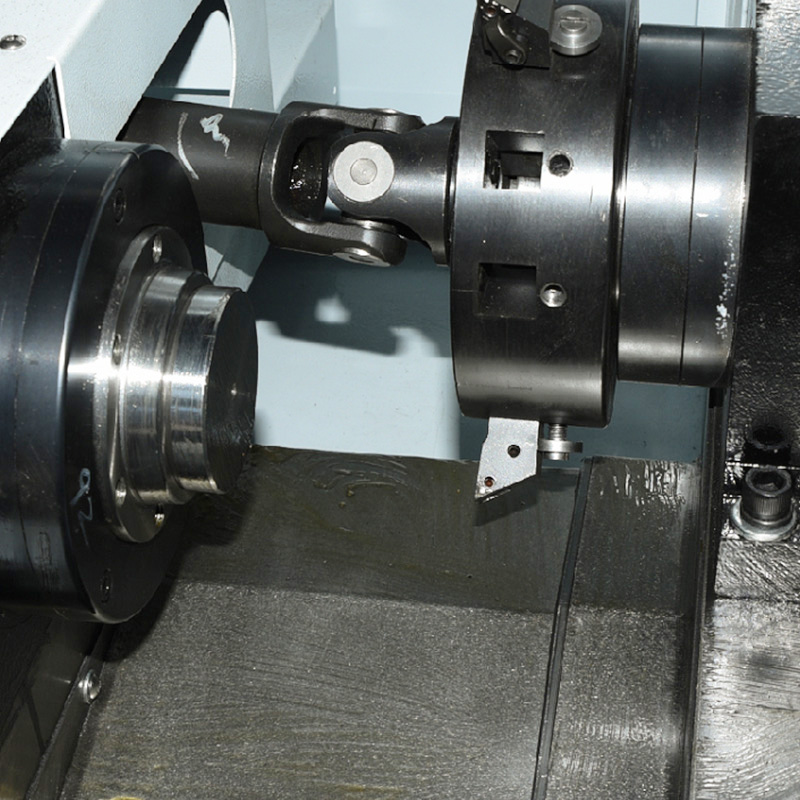

c) Ballscrews and Motors:

Ballscrews are used to convert rotational motion from the motor into linear motion along the guide rails. The motor drives the ballscrew, enabling precise movement of the CNC machine's working components, such as the cutting tool or workpiece.

d) CNC Control System:

The CNC control system sends instructions to the machine's motors and components, ensuring that the linear guides move in accordance with the programmed path. This system provides real-time adjustments and allows for the precise execution of machining tasks.

Linear guide CNC machines offer several advantages that enhance their performance and make them suitable for a wide range of applications. The primary benefits of these machines include:

a) High Precision and Accuracy:

Linear guides provide smooth and stable movement, which is crucial for tasks that require high precision. The rolling elements inside the guides minimize friction, reducing the chances of vibration and backlash, both of which can negatively affect machining accuracy. As a result, linear guide CNC machines are ideal for creating parts with tight tolerances, ensuring consistent quality.

b) Improved Speed and Efficiency:

Because linear guides allow for frictionless movement, CNC machines equipped with them can achieve faster speeds without compromising accuracy. The reduced friction also results in less heat generation, which can extend the machine's operational life. This combination of speed and efficiency makes linear guide CNC machines suitable for high-volume production and rapid prototyping.

c) Longer Machine Life:

The low-friction movement provided by linear guides reduces wear and tear on the machine components, extending the lifespan of the CNC machine. The reduced friction also minimizes the need for regular maintenance, making these machines more cost-effective in the long run.