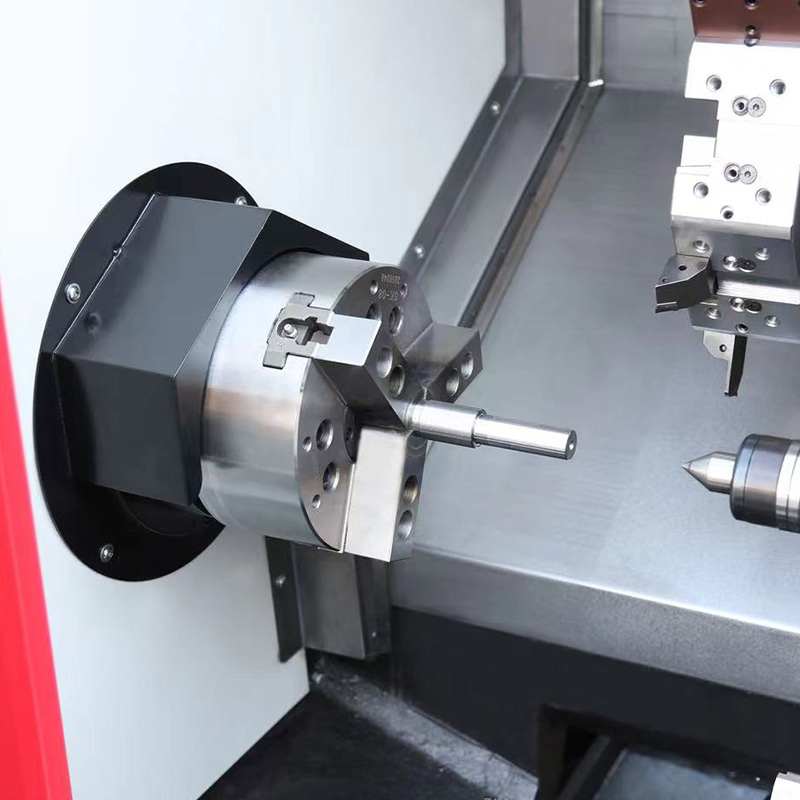

CF32 Hydraulic Clamping CNC Polygon Turning Machine

Cat:Small Polygon Lathe

CF32 hydraulic clamping CNC polygon lathe is designed for milling small and medium-sized high-precision parts, which can mill square, octagonal, hexag...

See DetailsIn the world of precision machining, the CNC polygon lathe stands out as a critical tool for producing complex, high-precision polygonal shapes. This specialized machine has become indispensable in industries that require intricate geometries, such as automotive, aerospace, electronics, and metalworking. The design of the CNC polygon lathe involves careful consideration of mechanical, electrical, and software components to ensure performance, efficiency, and precision.

A CNC polygon lathe is a type of turning machine designed specifically to produce polygonal shapes (such as squares, hexagons, and other multi-sided geometries) from a cylindrical workpiece. Unlike traditional lathes that are typically used to create round or cylindrical objects, the polygon lathe is engineered to cut or shape materials into flat sides, making it ideal for parts such as bolts, nuts, couplings, and other components that require precise, multi-faceted profiles.

The lathe's design allows it to convert a rotating workpiece into a polygonal shape through the use of a rotating cutting tool and advanced CNC control. The precise motion control of the cutting tool, combined with the ability to set specific angles and depths, ensures that the final product meets stringent dimensional tolerances.

The design of a CNC polygon lathe is a combination of several key components that work together to ensure accuracy and efficiency during the machining process. These components include the machine bed, spindle, tool holder, CNC control system, and the cutting tool itself. Below, we will examine the design of each of these components in detail.

The machine bed forms the foundation of the CNC polygon lathe, providing the necessary stability to withstand the forces exerted during cutting operations. Typically made of high-quality cast iron or other rigid materials, the bed is designed to vibrations, which can bring about inaccuracies in the machining process. The machine’s frame must also be designed to accommodate the movement of the spindle and tool holder, ensuring smooth and precise operation.

The bed's design also includes rails and guides for the sliding movements of the spindle and tool holder. These must be precision-machined to ensure minimal play and consistent movement during machining. In addition, the design of the bed accounts for the need to handle high rotational speeds without introducing any structural flexing or bending that could compromise precision.

The spindle is a critical component in any CNC lathe, and in a polygon lathe, its role is even more important. It is responsible for rotating the workpiece, typically at very high speeds, ensuring that the material is precisely positioned for the cutting tool to create the desired polygonal shape. The spindle must be designed to handle the torque and vibration that come with high-speed rotations.

To achieve performance, the spindle of a CNC polygon lathe is often supported by high-precision bearings that any radial or axial play. This ensures that the workpiece remains stable during cutting, which is essential for producing parts with tight tolerances.

The heart of the CNC polygon lathe is its computer numerical control system. This system is responsible for interpreting the operator’s commands and converting them into precise movements of the spindle, tool holder, and cutting tools. The control system is typically driven by a combination of software that can program tool paths, cutting speeds, and depth of cuts.

CNC control systems for polygon lathes are often equipped with advanced algorithms that allow for the creation of highly complex shapes with precise angular adjustments. These systems can also incorporate real-time feedback mechanisms, ensuring that the cutting tool moves exactly as needed to create the desired polygonal profile. The design of the control system also includes a user interface that enables operators to input settings, monitor progress, and troubleshoot any potential issues during machining.